2. CAx-Integrated Algorithms and Software

Fiber-reinforced composites are a vital subcategory of composite materials, characterized by their lightweight and high-strength properties. Their anisotropic nature and broad design space enable them to meet diverse application requirements. However, these same characteristics also pose significant challenges for design optimization. In aerospace applications, where performance and weight requirements are extremely stringent, careful design is required to achieve an optimal balance. Conventional design methods, which mostly rely on experience and trial-and-error, are suitable for simple applications but fail to address complex challenges. Examples include aircraft tire design, which involves complex internal geometries and large deformations during use, as well as components subjected to significant fluid-structure interaction, such as engine fan blades and wings. To tackle these challenges, this research proposes a forward design paradigm based on isogeometric analysis. It develops specialized kernels and core algorithms to support the creation of industrial-grade forward design software, with initial applications in areas such as aircraft tires. By leveraging innovations in core algorithms, this research utilizes the coupled effects of fluid fields and curved-surface components to co-optimize parts such as engine fan blades and wings – particularly those based on curved elastomer composites – thereby maximizing propulsion efficiency. The core objective of this research is to develop a unified algorithmic and software framework to address the challenges discussed above, as detailed in the following subsections.

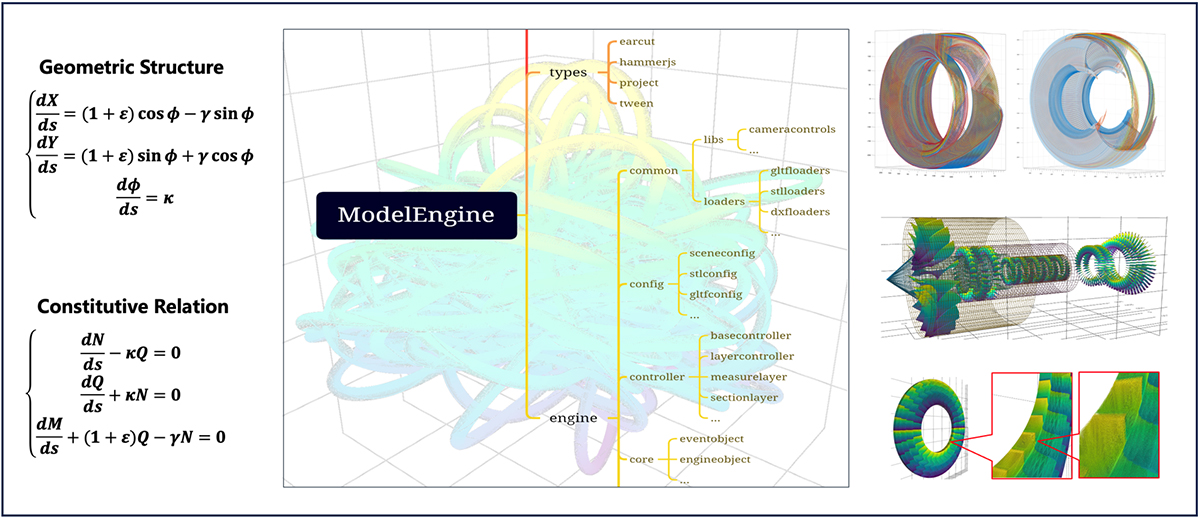

2.1 Underlying Logic and Core Algorithms for CAx Integration

Despite the widespread use of CAD, CAE, and CAM tools, issues such as data fragmentation, serial workflows, and iterative design-analysis loops persist. These problems stem from their reliance on different geometric representations and incompatible modeling systems, which lack a unified underlying logic. This research focuses on solving the challenge of “geometry–physics–manufacturing” consistency in CAx integration, rather than aiming for a universal platform. It delves into common computational kernels, exploring integrated modeling paths based on implicit geometric representations and unified topological frameworks. Coupled data structures are developed to map variables directly to analysis fields and manufacturing processes, enabling the construction of differentiable geometry engines and cross-domain sensitivity analysis algorithms for end-to-end tracking from structural changes to performance outcomes. Key breakthroughs include joint optimization strategies for multi-domain parameter spaces, enabling design adjustments to simultaneously drive updates in structural simulations and re-planning of process parameters. The goal is to realize the seamless transmission of design intent at the level of mathematical representation and computational logic, not just superficial integration, providing verifiable algorithm prototypes and core components for “one-time modeling, multi-domain driving, closed-loop optimization” CAx integration.

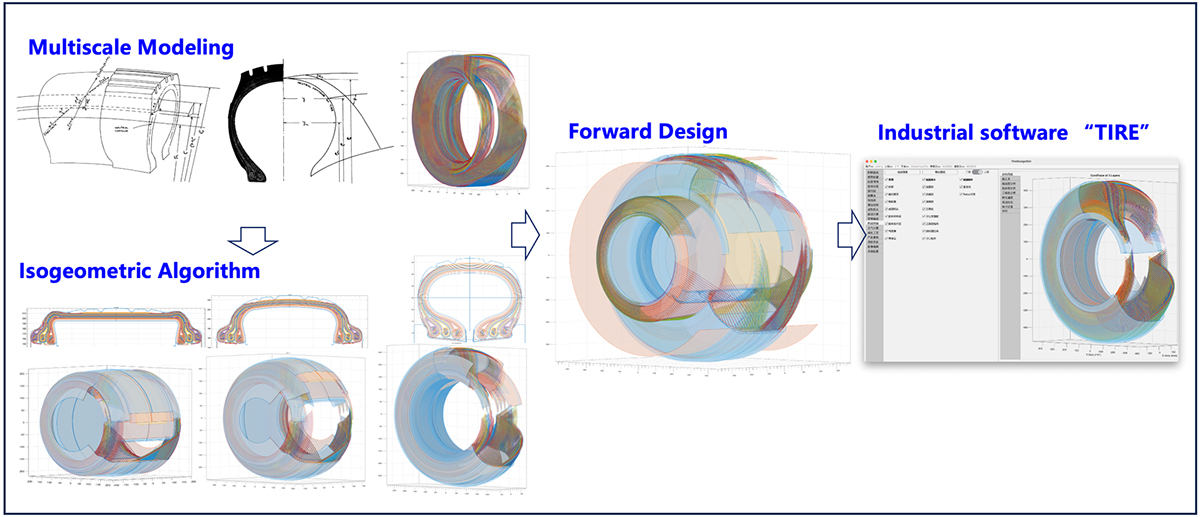

2.2 Industrial Software (TIRE) for Digital Tires

The macroscopic performance of aircraft tires under extreme service conditions—including strength, toughness, dynamic load-bearing capacity, and durability—is governed by their multi-scale structure, particularly the mesoscale geometric configurations and interfacial behavior. Traditional trial-and-error development makes it challenging to achieve precise control over tire performance due to the complexity of their multi-scale structures. This research focuses on developing a macro-meso cross-scale forward design paradigm for aircraft tires using isogeometric analysis (IGA). By employing differential forms as the geometric kernel to describe the material distribution within tires and its evolution during manufacturing processes, this approach systematically reveals the intrinsic chain connecting the selected materials to mesoscale composite structures and, ultimately, to the macroscopic performance of finished and semi-finished tire products. An optimization strategy is employed to dynamically simulate the material distribution changes during the tire building process for a non-natural equilibrium profile constructed by the carcass cord skeleton and constrained by component rubbers. This approach establishes an integrated digital tire forward design process that combines structural and process design, and results in a suite of digital tire industrial software, thereby providing new design methods and tools for the forward development of aircraft tires.

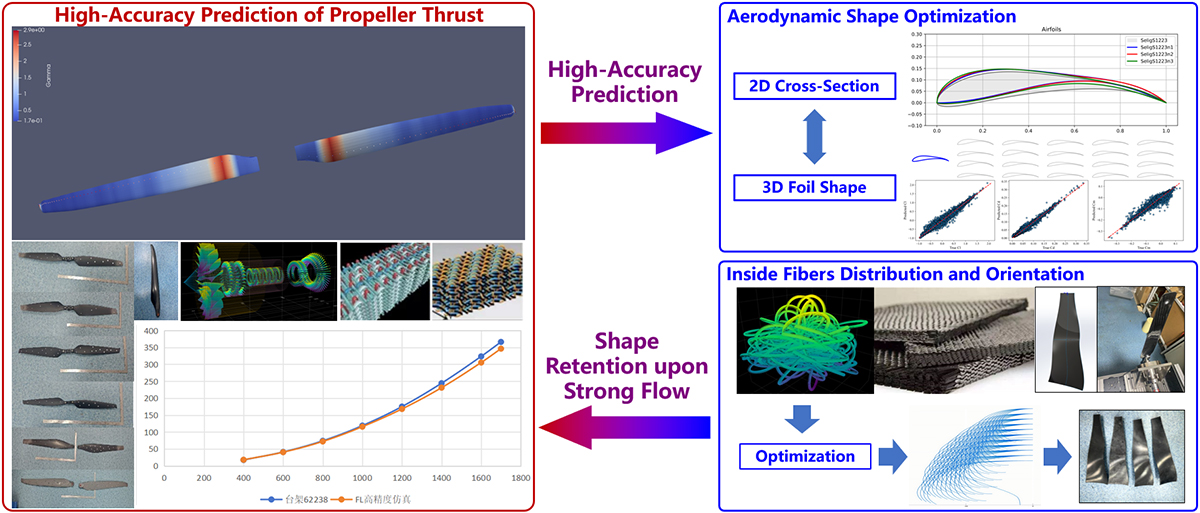

2.3 Fluid-Structure Interaction (FSI) Design for Fiber Composites

Fiber-reinforced polymer composites, renowned for their lightweight, high strength, high fatigue resistance, damping properties, and ease of integrated curved-surface forming, are ideal materials for aerospace blades and wings. However, their design has long been constrained by insufficient simulation accuracy, time-consuming iteration cycles, and the lack of coordination between external shape and internal structure optimization, which limits the full realization of their performance potential. Focusing on fluid-structure interaction (FSI), this research develops a high-precision, orders of magnitude faster performance simulation system for blades and wings. This system significantly reduces prediction errors and enables real-time, reliable computational support for the design process. Based on this framework, two key optimization strategies are proposed:

- Aerodynamic Shape Optimization: An AI-driven, fully automated optimization framework is developed for the aerodynamic shapes of 2D sections and 3D airfoils. This framework overcomes the speed bottleneck while ensuring high accuracy verified through experiments.

- Aeroelasticity Optimization: New mathematical models and solvers are proposed and implemented to address the aeroelastic behavior of anisotropic composite blades and wings. Integrated with deep learning algorithms, this approach enables the optimal design of the spatial layout of fibers within composite components.

We have developed AeroPredict, a two-dimensional airfoil aerodynamic performance prediction platform. Based on our proprietary “Airfoil Selective Fusion Neural Network” framework, it enables efficient, robust, and highly accurate prediction of airfoil aerodynamic characteristics. The platform provides an airfoil parameterization interface, bridging aerodynamic shape generation and performance evaluation to form an integrated design-prediction closed-loop system. The prediction platform is as follows:

Airfoil Aerodynamic Performance Prediction Website AeroPredict: http://aeropredict.ciac.jl.cn/