Project Description

Abstract:

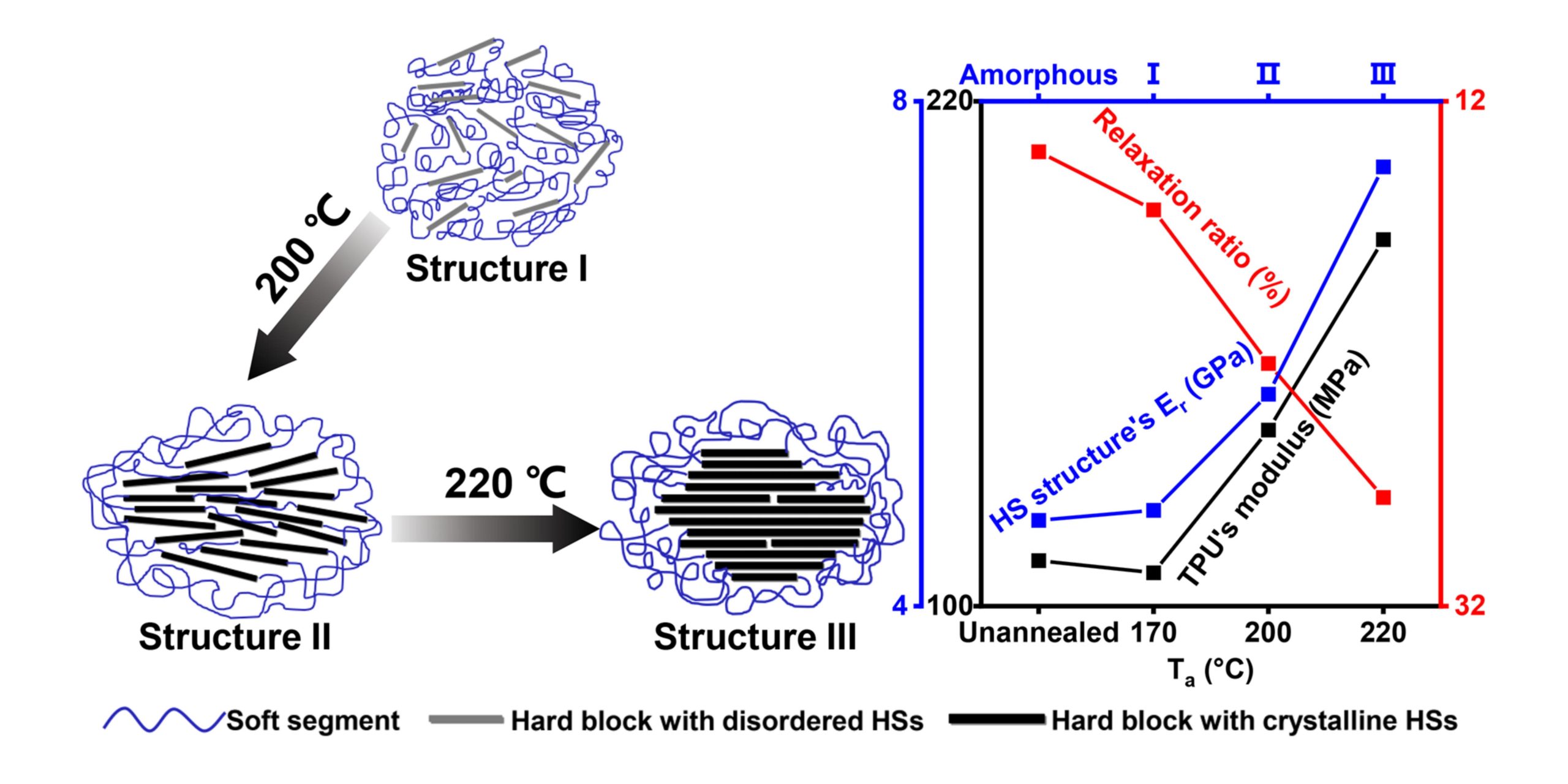

Performance optimization of thermoplastic polyurethane (TPU) is hindered by the mysterious structure–property relationship due to intricate hard segment (HS) aggregation structures. Here, a typical MDI-BDO-based TPU was employed as a model to investigate the HS aggregation structures from multiscale morphology, and different annealing conditions were applied to transform them to effectively manipulate TPU’s mechanical properties. The pristine TPU has three HS aggregation structures. Structure I is hard domains with irregularly stacked hard blocks and disordered HS packing, while structures II and III are crystalline hard domains with loosely and compactly stacked hard blocks, respectively. Therefore, the reduced moduli (Er) of structures II and III are 19 and 57% higher than that of structure I, respectively. Annealing at 170 °C enlarged structure I but decreased its number density, slightly lowering TPU’s modulus to 108.0 from 110.8 MPa. Annealing at 200 and 220 °C reorganized less ordered HSs into crystalline structures II and III, respectively, which significantly enhanced TPU’s modulus to 141.8 and 187.1 MPa, respectively. For viscoelasticity, TPU’s stress relaxation resistance decreased with annealing temperature because 170, 200, and 220 °C very slightly, partly, and completely broke the hard domain’s long-range connectivity, respectively. This work elucidated the evolution of HS aggregation structures during annealing, which provides guidelines for TPU’s performance optimization and design. [PDF]