|

I. Device Fabrication |

|

1. A state-of-the-art solar cell fabrication line including spin coater, substrate treatment, electrode deposition, device encapsulation, I-V and aging measurement. |

|

|

|

|

|

2. Two spin coaters from Laurell |

|

|

|

|

|

3. Spraying system |

|

|

|

|

|

4. A screen printing equipment |

|

|

|

|

|

5. Two thermal evaporators |

|

|

|

|

|

6. An ultraviolet ozone cleaning system |

|

|

|

|

|

II. Device Characterization |

|

1. AAA class (Certification from JIS C 8912, ASTM E927-05, IEC 60904-9 criterions) solar simulator with an effective irradiated area of 70 mm×70 mm; |

|

|

|

|

|

2. A measurement system for polymer photovoltaic module; |

|

|

|

|

|

3. Keithley 237/Keithley 2400 source meters for four-probe experiment and current-voltage sweep; |

|

|

|

|

|

4. Incident photon to current efficiency (quantum efficiency) measurement system with Newport xenon light source; |

|

|

|

|

|

5. Closed liquid helium cryogenic system (10K~500K) with lakeshore temperature controller |

|

|

|

|

|

6. Two lifetime measurement equipments for solar cells |

|

|

|

|

|

7. A vacuum freeze drying equipment; |

|

|

|

|

|

III. Morphology & Metrology |

|

1. A 5420 Atomic Force Microscope |

|

|

|

|

|

2. A D-100 surface profiler from KLA-Tencor |

|

|

|

|

|

3. A Brookfield DV-III ULTRA Rheometer with programmable controller; |

|

|

|

|

|

4. SEM, EDX, TEM, XPS, UPS, XRD and Ellipsometer (in public lab); |

|

|

|

IV. Spectroscopy Analysis |

|

1. A PerkinElmer Lambda 750 UV/VIS/NIR spectrophotometer; |

|

|

|

|

|

2. High perfomance optical microscope from Olympus; |

|

|

|

|

|

3. Steady/transient states and time resolved fluorescence spectrometer with two picosecond laser excitated sources from Edinburgh Instruments; |

|

|

|

|

|

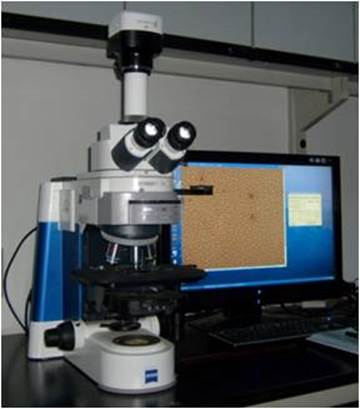

4. A Carl Zeiss polarizing microscope |

|

|

|

|

|

5. A gas chromatograph station |

|

|

Equipmentslyricz2020-03-23T20:14:47+08:00