4. Functional Elastomers and Devices

Functional elastomers, a class of polymers endowed with specialized functionalities, play pivotal roles in aerospace, defense technologies, high-end medical devices, and intelligent sensing systems. Developing elastomers and devices with specific functionalities is a key strategy for addressing national strategic needs and enhancing independent innovation in high-end equipment. Functional elastomers are essential for diverse cutting-edge applications (e.g., bionic organs, flexible electronics, extreme-environment tires, and stealth technologies) because of their unique and often irreplaceable properties. This research focuses on four key application domains: biomedical elastomers, radiation-shielding materials, flexible mechanical sensors, and aircraft tires. The research adheres to an integrated R&D process encompassing molecular design, material synthesis, cross-scale structural design, and precise device/component fabrication. By analyzing the correlations and quantifying the relationships between specific chain structures and corresponding material properties, the precision of molecular design in guiding the synthesis process is significantly improved. Composite modification and interface functionalization are employed to tailor mechanical properties and achieve target application functionalities. The aim is to deliver functional elastomers and devices that offer high tissue compatibility, outstanding shielding and/or absorption, wide-ranging and sensitive responses, and long-term reliability to achieve an integrated synergy between material innovation and manufacturing.

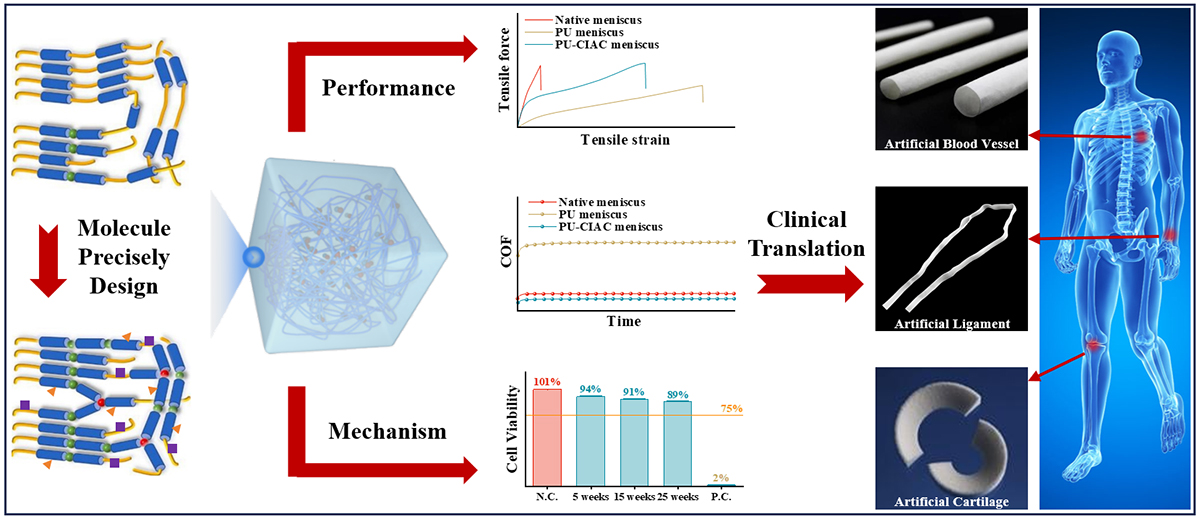

4.1 Biomedical Elastomers

Most human tissues are soft and elastic, making elastomeric polymers ideal candidates for biomedical materials from a mechanical matching perspective. They are widely used in medicine for repairing or replacing tissues and organs. However, as materials that come into direct contact with or are implanted in the body, elastomers must also exhibit excellent biocompatibility, tailored functionality, and a favorable biological response. As a result, designing and synthesizing elastomers with well-balanced multifunctional properties has become a major research focus. This research involves precise design and control of polymer molecular structures, introducing bio-functional modifier units. It investigates the influence of chain and condensed-state structures on mechanical strength, tribological behavior, and cell/tissue compatibility, revealing the underlying patterns and mechanisms. The aim is to endow elastomers with specific biomechanical strength, in vivo stability, and biological functions, laying the technical foundation for the clinical translation of biomedical elastomers (e.g., artificial cartilage, small-diameter artificial blood vessels, artificial ligaments, artificial muscles).

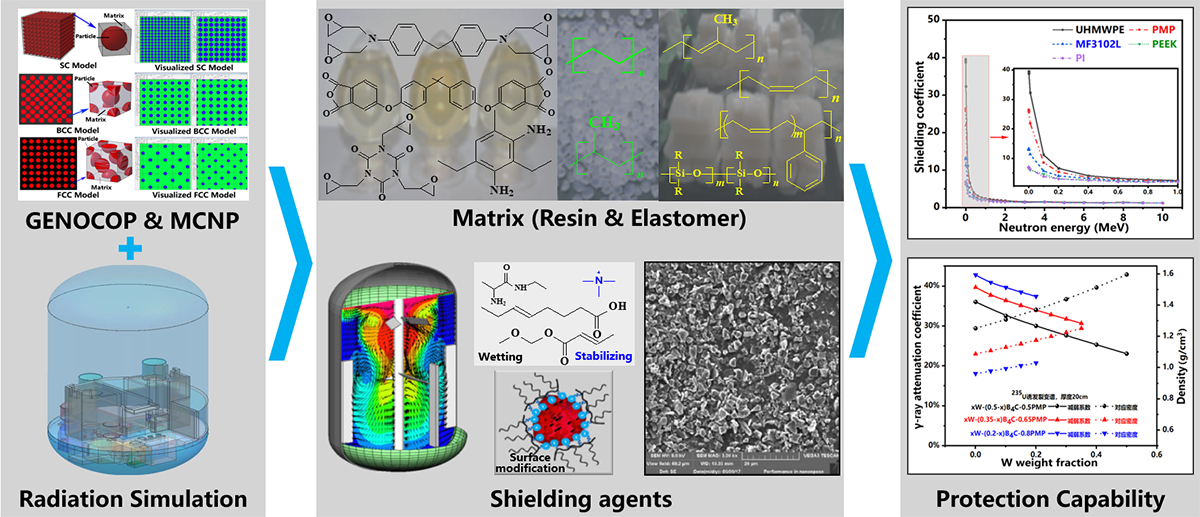

4.2 Radiation-shielding Materials

Nuclear radiation protection is a prerequisite for ensuring the normal operation of nuclear power facilities, the safety of personnel, and environmental protection. Appropriate materials are essential to achieving effective radiation protection. This research integrates genetic algorithms, particle transport models, high-precision 3D simulation, and other technologies to perform constrained multi-objective optimization of material systems. Based on this, different polymer elastomer matrices are selected and compounded, targeting diverse application scenarios and requirements. Effective organic/inorganic/metal heterogeneous interface compounding in complex elastomer systems is achieved through surface modification. The synergistic effect of composite constituents and processes prevents sedimentation of high-density compositions, ensuring high material uniformity. The trade-off between the high filler content required for effective shielding and the demands for processability, mechanical integrity, and thermal stability is effectively resolved. The entire process chain from material development, engineering pilot test, to stable batch production is integrated, aiming to provide products with excellent shielding performance while meeting strict constraints on volume and weight, thereby providing key material support for the modernization of important national equipment.

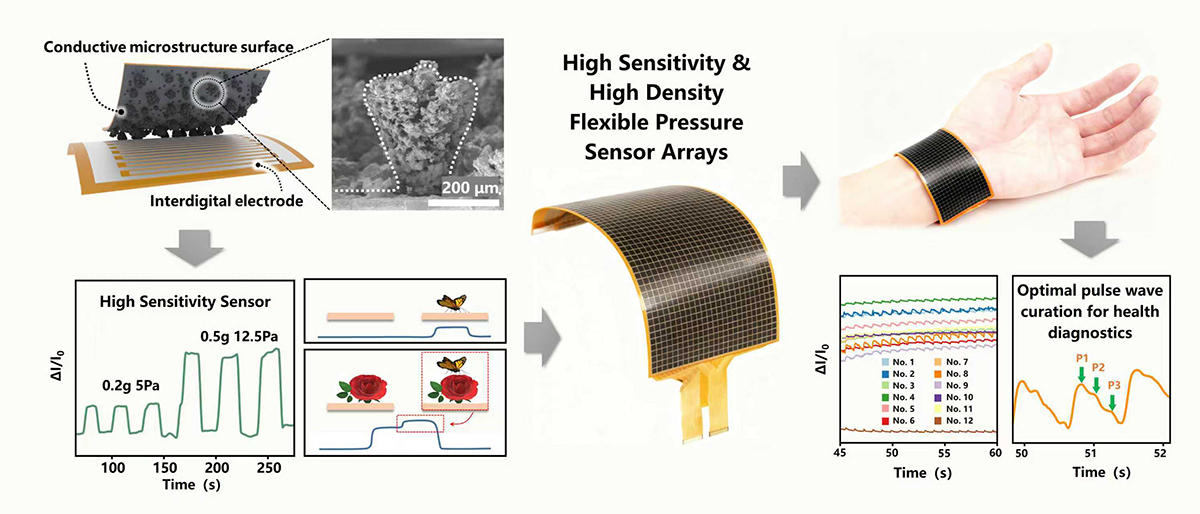

4.3 Flexible Mechanical Sensors

Flexible mechanical sensors, characterized by thinness, lightness, and array capability, hold unique advantages in interface pressure distribution detection. They are typically fabricated using polymer elastomers, conductive nanomaterials, and micro/nano-processing/printing techniques. However, their performance metrics (e.g., measurement range, fatigue life, and accuracy) still lag behind traditional silicon-based sensors, largely due to an incomplete understanding of how mechano-electric coupling mechanisms interact with dynamic microstructural evolution. High-density array integration brings new issues like unit consistency and signal crosstalk. Focusing on the micro-structured piezoresistive response mechanism, this research investigates the influence of microstructure morphological evolution on array linearity and consistency. It reveals the intrinsic mechanisms of mechano-electric coupling characteristics of the materials within the conductive layer, which affect the piezoresistive interface contact behavior, fatigue decay, and signal drift of the sensor. This provides theoretical guidance for designing high-performance, high-density flexible mechanical sensor arrays, promoting their application in more reliable and precise detection within aerospace, semiconductors, and other fields.

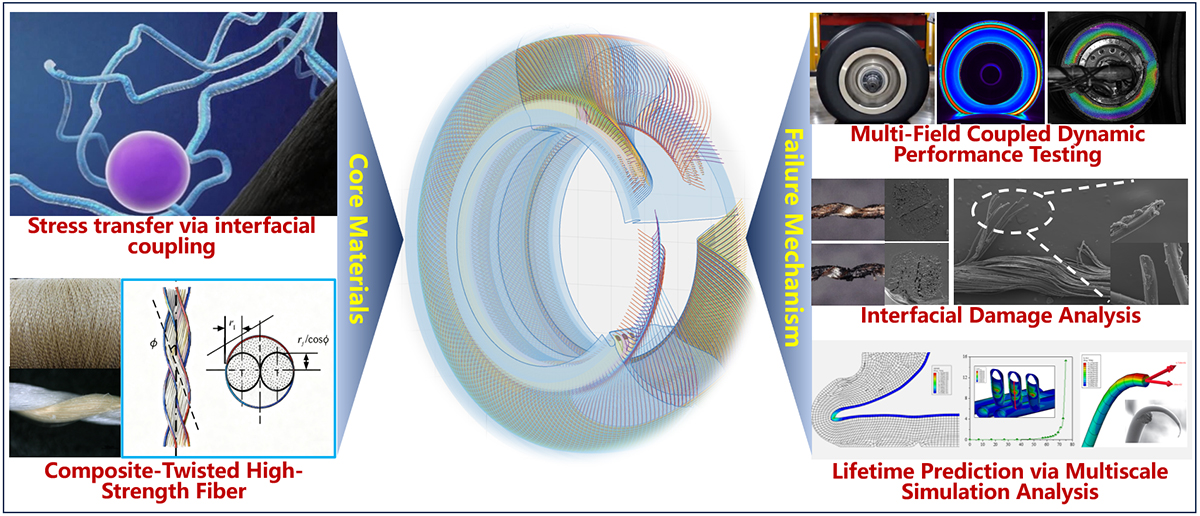

4.4 Aircraft Tires

Aircraft tires are the only parts of an aircraft contacting the ground during takeoff and landing, directly impacting flight safety. Ensuring reliability throughout the entire life cycle of the tire is the core of product development. Currently, Western countries lead in aircraft tire technology, particularly in civil aviation. Over the past century, product iterations have closely followed aircraft advancements, resulting in extensive experience and well-established databases. This research focuses on simultaneously enhancing the reliability and service life of aircraft tires. Starting with Bionic Rubber as the key material, mathematical methods guide formulation development to achieve synergistic optimization of multiple objectives, including anti-wear, fatigue resistance, and high adhesion. Leveraging a self-developed TIRE industrial software platform, the research achieves high-precision integrated design across the entire tire production process: structural design, performance prediction, and tire building. Rheological analysis enables precise dimensional control of rubber components, ensuring tire manufacturing accurately reproduces design intent. The ultimate goal is to develop aircraft tires meeting the needs of different application fields, thereby promoting technological progress across the industry.