3. Wear-Resistant Elastomers and Tribological Behavior

Over 80% of failures in moving parts of mechanical equipment originate from wear, while friction during operation consumes significant energy. Thus, reducing friction and wear is crucial for extending service life and lowering energy consumption. Polymer materials, known for their light weight, corrosion resistance, toughness, and self-lubricating properties, are important multifunctional wear-resistant materials. Elastomers, a key subset of polymers, exhibit notable mechanical properties, a broad range of adjustable moduli, and superior toughness and elasticity. Consequently, under water-based lubrication, elastomers readily form favorable interfacial compatibility with counterparts. These properties give elastomers superior resistance to high-speed erosion, tearing, and abrasive wear, rendering them highly suitable and often irreplaceable in such conditions. This research encompasses the development of base friction materials, the design of material-structure integrated composites, and their engineering applications across diverse lubrication conditions and use cases. It aims to clarify friction behavior and corresponding wear mechanisms under various conditions, proposing material and structural design concepts like “using softness to overcome hardness” to solve wear challenges under extreme conditions such as ultra-high-speed particle erosion, high-speed tearing, and high temperature/high load.

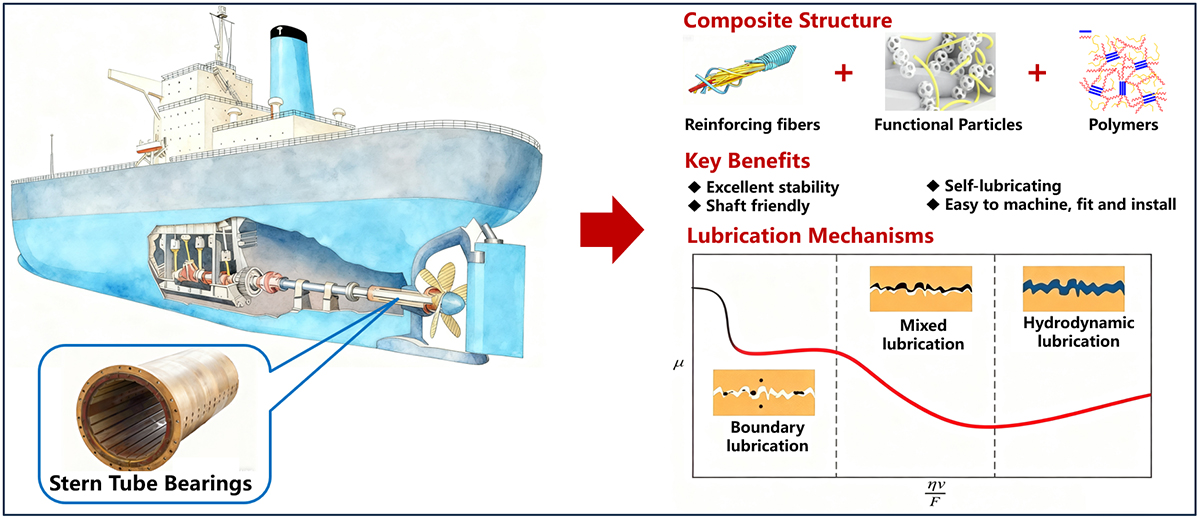

3.1 Water-Lubricated Friction Materials and Wear Mechanisms

Water-lubricated friction materials, which use water as the lubricant, are key categories integrating friction reduction, wear resistance, and sealing functions. The demand for environmental friendliness, safety, and sustainability in high-end equipment across transportation, energy, and defense sectors requires bearings and seals made of these materials to possess core properties of low wear, self-lubrication, and high reliability. This research begins with a mechanistic analysis, investigating the differences in adhesion and abrasive wear behaviors across various materials to clarify the root causes of surface damage, wear debris accumulation, and final failure, ultimately establishing material pairing rules for friction counterparts. This research has not only established structural design methods for wear-resistant elastomers but also achieved breakthroughs in key technologies, including the design of high-toughness fiber skeleton architectures, matrix resin modification, controlled release of self-lubricating compositions (e.g., PTFE particles), and enhancement of toughness and wear resistance. Based on this, a comprehensive performance evaluation system covering load capacity, extreme condition adaptability, and service life of water-lubricated friction materials has been established. The successful development of multiple series of high-wear-resistant materials (rubber-based, polyurethane-based, phenolic-based) for water-lubricated bearings and seal friction pairs has provided critical support for national strategic equipment security and technological advancement.

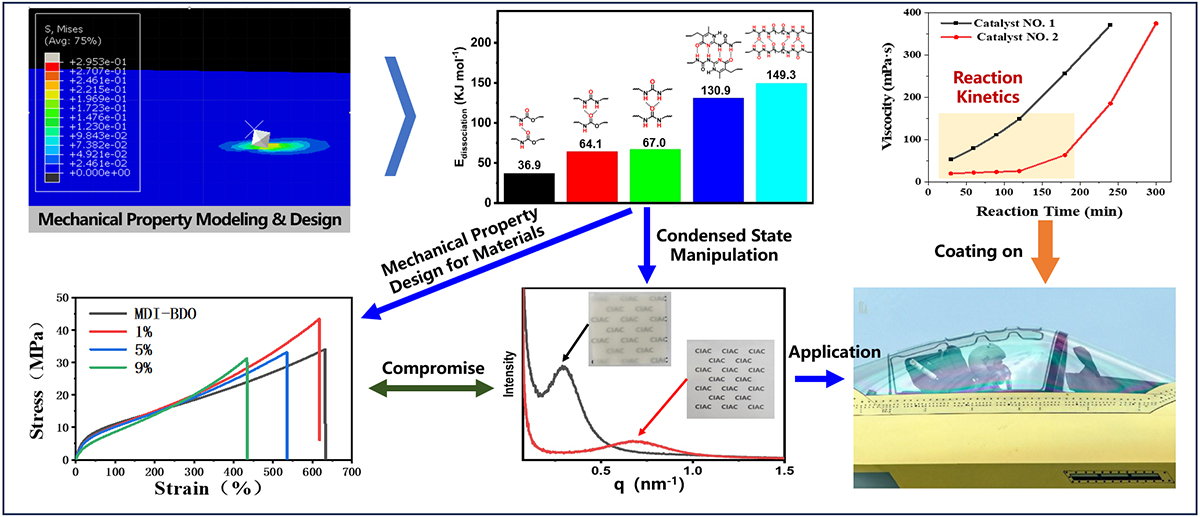

3.2 Erosion Wear Mechanisms and Optical Coating Construction

Aero-optical windows are key components for information exchange between aircraft and the external environment. Functional structural coatings on their outer surfaces are designed to ensure accurate and efficient optical communication. The service conditions of aircraft dictate that these windows endure high-speed, even supersonic, erosion wear from wind-blown sand, ice crystals, and raindrops. Therefore, developing multifunctional wear-resistant optical coating technology is essential to meet growing functional demands and ensure reliability under such erosion. This research starts from designing the molecular structure of optical materials, aiming to construct units for energy absorption and physical dissipation by manipulating their condensed states. The core objective is resolving the trade-off between optical and mechanical properties, ultimately ensuring resistance to high-speed particle erosion. This research establishes the correlation between reaction kinetics and rheology to develop coating application techniques that meet the optical requirements for windows of different sizes and curvatures. This ultimately establishes a full-chain technical system—from material design to deposition processes—to fully satisfy the optical performance and harsh service environment required by aero-optical windows.

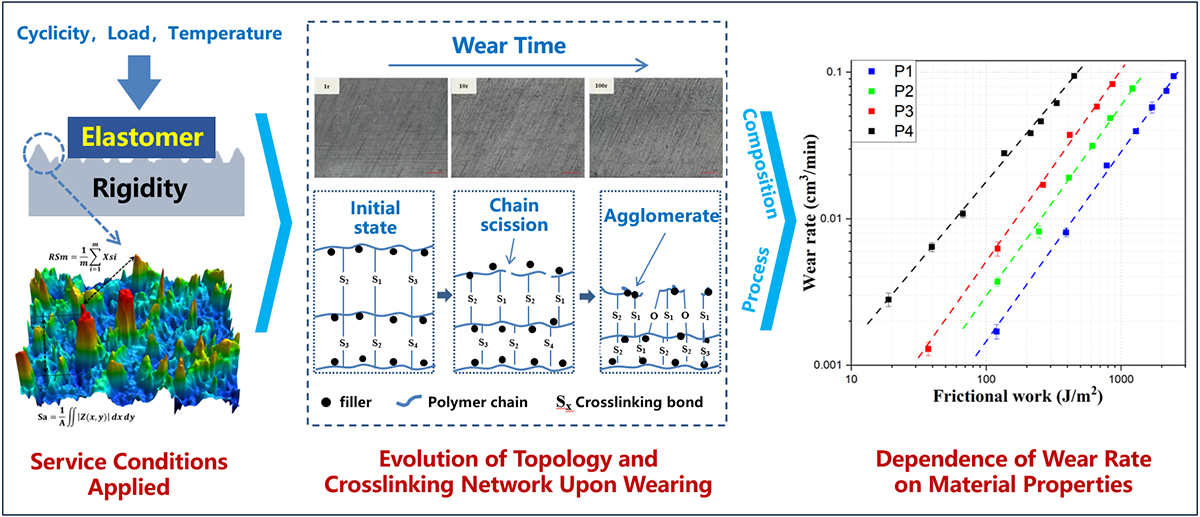

3.3 Anti-Tear Wear and Lifespan Enhancement

In friction pairs comprising elastomers and rigid bodies, cyclic dynamic friction causes micro-cracks in the elastomer, which propagate into macroscopic tears until spalling generates wear debris. This wear process is a progressive failure resulting from the long-term combined action of mechanical force, heat, and oxygen on the elastomers. Conventional static mechanical characterization can no longer effectively predict material wear life. This research involves developing test equipment to equivalently simulate actual friction conditions, accurately replicating characteristic parameters like friction energy density, frequency, and surface roughness. An energy dissipation model that couples hysteresis heating and friction heating under different harsh friction processes is established. The evolution of chemical and physical crosslinking networks at different friction time scales is quantified to identify the dynamic and static mechanical properties significantly affecting wear rate. Subsequently, targeted improvements are made through composition design, substantially extending the anti-tear wear life of elastomers.

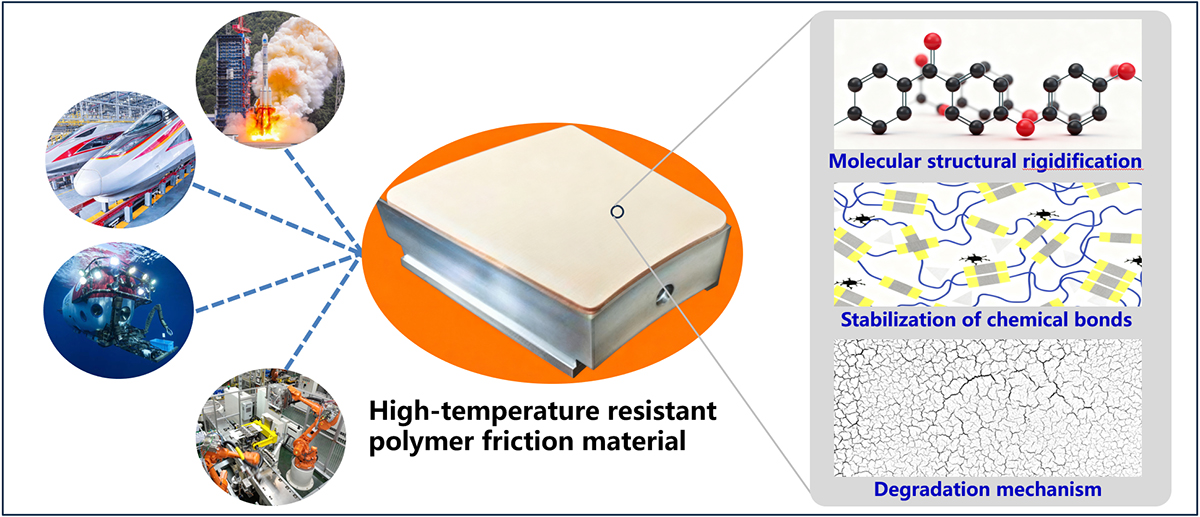

3.4 High-Temperature Wear-Resistant Polymer Composites

Most common polymer friction materials have long-term service temperatures below 200°C, easily losing functionality at high temperatures due to thermal decomposition, softening, creep, or accelerated aging. Addressing the needs of high-temperature sliding friction components in high-end equipment such as aerospace, rail transport, deep-sea/polar regions, and precision machinery, this research develops novel high-temperature wear-resistant polymer composites. These retain the lightweight and processability of polymers while maintaining stable performance under extreme temperatures and mechanical stress. Guided by the principles of “Enhancing molecular rigidity, stabilizing chemical bonds, inhibiting degradation pathways,” high-thermal-stability matrix resins like polyimide, polyetheretherketone (PEEK), and polyphenylene sulfide (PPS) are designed, synthesized, and modified. The interfacial compatibility and dispersion uniformity of reinforcing phases (e.g., carbon fibers, aramid fibers, inorganic particles) that provide wear resistance, self-lubrication, and thermal conductivity are optimized. The synergistic mechanisms of components are analyzed and quantitatively described. Evaluation methods for process reliability and long-term service stability of wear-resistant materials under high temperature, high speed, high load, and different lubricating media are established to clarify the relationship between operating condition adaptability and composite structure.