1. Material Synthesis and Performance Control

Elastomers such as Bionic Rubber and Polyurethane with predetermined properties can be synthesized through precise molecular design, tailored compositions, and controlled processing. Composite strategies can be employed to introduce additional tailored functionalities. Understanding the intrinsic relationships between multi-scale structures (from micro to macro) and their resulting properties is crucial for advancing elastomers toward high-end applications. Developing an accurate parameter system to characterize material performance under well-defined service conditions is essential for effective R&D. Specifically:

- Molecular design serves as the foundation for achieving precise control over material performance.

- Innovative synthesis methods improve preparation efficiency and ensure product stability.

- The use of multi-component formulations facilitates the development of high-performance, multifunctional elastomeric composites.

- Cross-scale structure–property relationships offer reliable guidance for developing application-specific elastomers.

1.1 Molecular Design for Elastomers with Precise Mechanical Properties

This research adopts a forward design paradigm grounded in inverse mapping from target properties, moving beyond traditional trial-and-error approaches. A hierarchical design strategy is proposed to achieve elastomers with desired chain architectures:

- Backbone design: Monomer selection determines the intrinsic chain flexibility, cohesive energy density, and glass transition temperature. Precise control of molecular weight and entanglement density determines the baseline mechanical strength.

- Crosslinking network design: A theoretical model is used to calculate the required crosslink density based on the target modulus. Carefully designing molecular structures of crosslinker controls bond energy and spatial distribution uniformity of crosslinks, which is essential for achieving precise mechanical properties.

- Secondary interactions and reinforcement units: Functional groups—such as hydrogen bonding or ionic clusters—can enhance the toughness of elastomers. As a prospective strategy, grafting modification can be employed to enhance interactions with fillers, thereby improving interfacial quality and stress transfer efficiency during service.

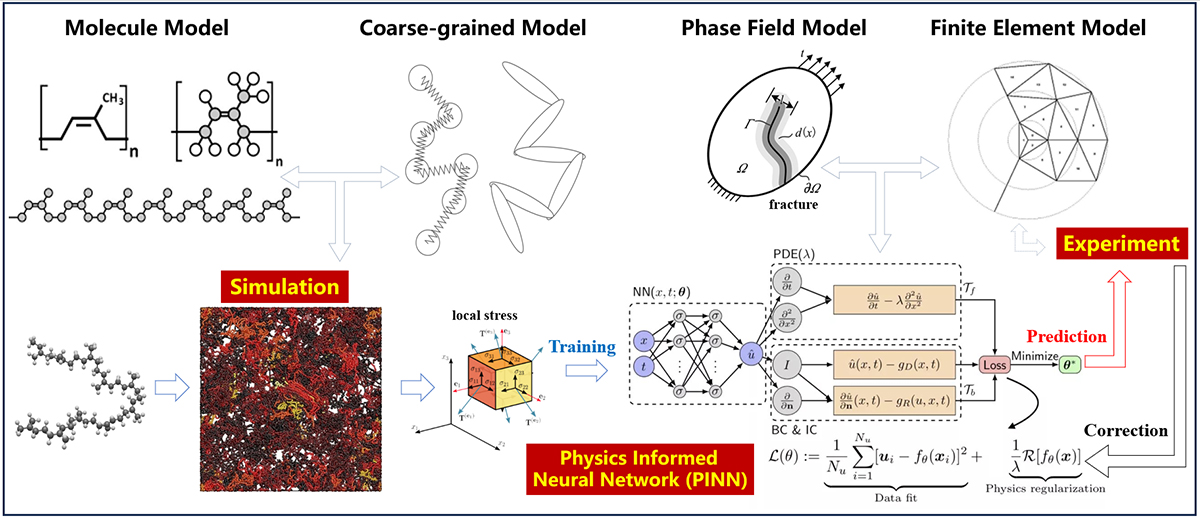

This hierarchical design should be supported by molecular dynamics simulations to predict aggregation structures and stress-induced evolution. Physics-informed neural networks (PINN) integrate experimental results to calibrate simulation parameters, establishing quantitative structure–property relationships for precise molecular design.

1.2 Controlled Synthesis and Functionalization of Elastomers

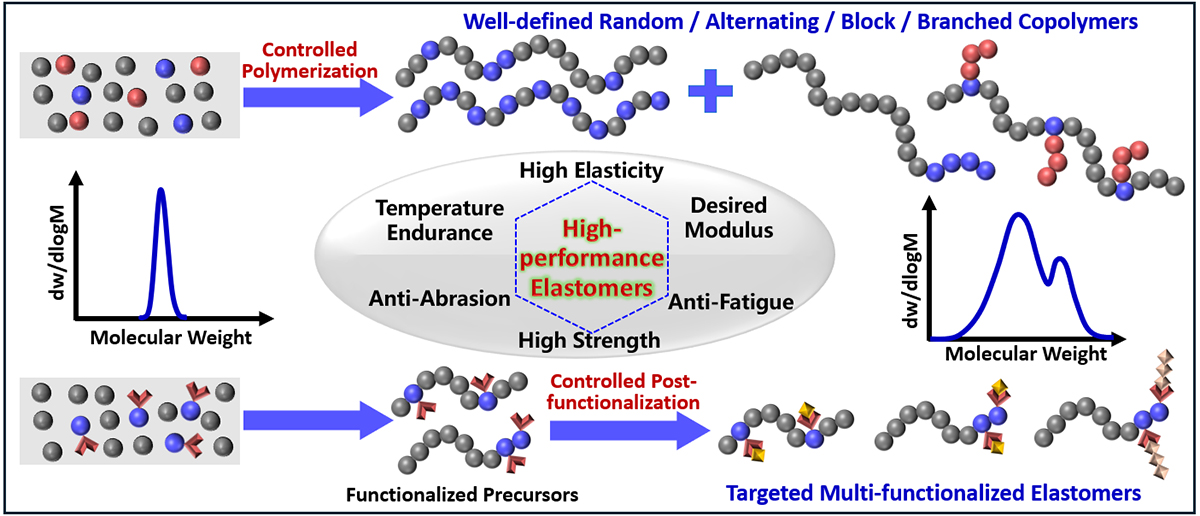

Sequence distribution, topology, functional groups, molecular weight and its distribution are fundamental variables defining elastomer performance. Current controlled polymerization techniques face challenges in precisely controlling sequence and topology. Additionally, the introduction of functional monomers often suffers from compatibility issues with active polymerization centers. This research focuses on:

- Developing synthesis methodology for elastomers with precise chain structure.

- Establishing a general strategy for controlled synthesis.

- Designing functional monomer and post-modification route to achieve simultaneous control over sequence, topology, and functionality.

A closed-loop “monomer design–controlled polymerization–functional modification” paradigm is envisioned, enabling precise synthesis of sequence-controlled, structurally diverse, and functionalizable elastomers. This expands performance boundaries and provides well-defined standard samples for elucidating “nano sequence–meso network–macro mechanics” cross-scale relationships and building predictive models.

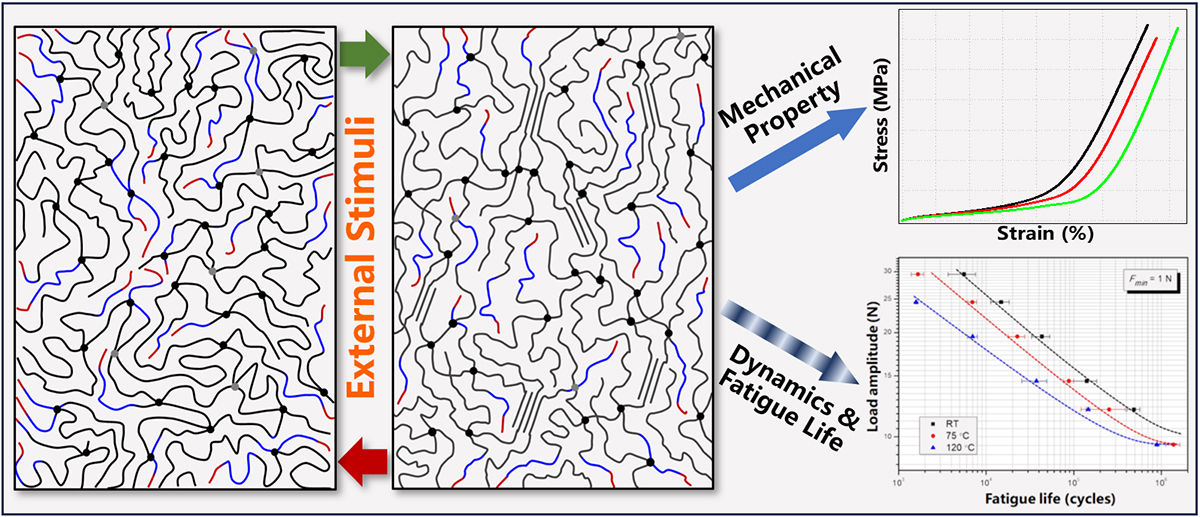

1.3 Multi-Level Structures of Elastomers and Their Relationship with Properties

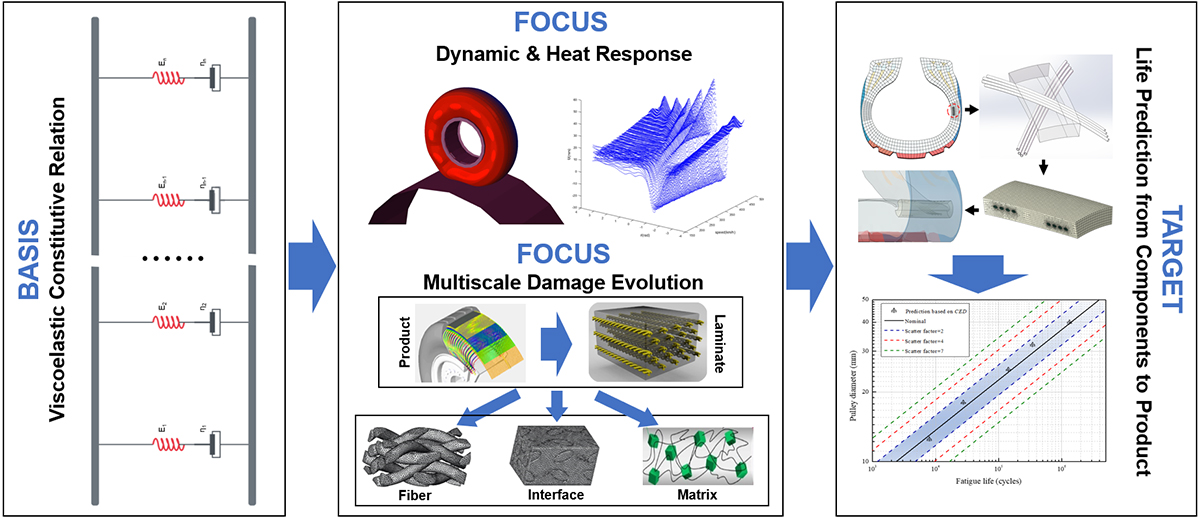

The long-chain nature of polymers gives rise to complex multi-level structures across chain and condensed-state scales. Compared to other polymers, elastomers exhibit low modulus and strength, rendering their mechanical properties highly sensitive to changes in condensed-state structure. Since elastomers are often used under dynamic loading conditions, their dynamic mechanical performance is particularly critical and highly dependent on their microstructure. During dynamic loading conditions, the structure and performance of elastomers may exhibit coupled dynamic evolution. Thus, the structure not only predetermines static properties but also governs dynamic response, damage evolution, and fatigue life.

This research aims to address the challenges associated with characterizing chain structures (e.g., copolymer segments, modified structures) and physical and/or chemical crosslinking networks. New methods for multi-level structural characterization and quantitative modeling will be developed to establish well-defined qualitative and quantitative structure–property relationships, thereby supporting the forward design of elastomers with customized performance.

1.4 Strength Reinforcement Mechanisms and Methods for Elastomers

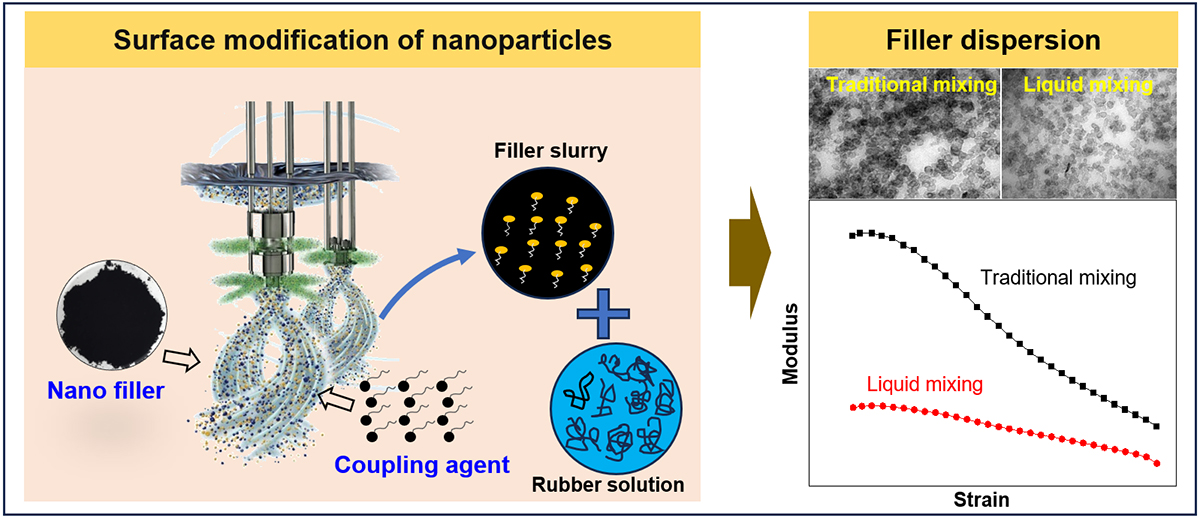

Incorporating nano-reinforcing particles significantly enhances the strength and modulus of elastomers, meeting the requirements for load-bearing, wear resistance, and fatigue resistance. The reinforcement mechanism is governed by interfacial interactions and particle dispersion, which are tightly coupled. Decoupling these factors and quantifying their respective contributions are essential for understanding the underlying reinforcement mechanisms.

This research focuses on:

- Efficient surface modification of nanoparticles

- Optimized liquid-phase mixing processes for elastomer composites

- Development of interfacial coupling agents with specific functional groups to prevent nanoparticle agglomeration and independently tailor interfacial interactions

This enables the development of highly decoupled mechanical reinforcement models, which quantitatively reveal how the multi-scale structure of nano-fillers and their physicochemical interactions with elastomers influence composite performance. High-performance reinforced elastomer composites incorporating nanomaterials such as carbon nanotubes, graphene, carbon black, silica, and other nano-fillers with diverse morphologies are developed to meet the requirements of applications in aircraft tires, air springs, and aerospace seals.

1.5 Dynamic Mechanics and Fatigue Failure

Components of a product made of elastomers are frequently subjected to cyclic deformation, heat buildup from fatigue, and high-frequency mechanical impact. The nonlinear dynamic mechanical response directly influences in-service performance, whereas fatigue limits determine reliability. Evaluating dynamic reliability poses a significant challenge due to the strong dependence of dynamic behavior on strain, time, and temperature, the complex pathways of energy dissipation under fatigue loading, and pronounced thermo-mechanical coupling. Due to the large modulus mismatch between the composite constituents (e.g., elastomer matrix and fillers), interfacial interactions and particle agglomeration directly affect stress concentration, micro-damage initiation, and the macroscopic service life.

This research aims to develop constitutive models that can describe nonlinear, finite-deformation, and viscoelastic behavior, enabling accurate transient and multi-field coupled dynamic analysis of elastomer-based components under complex loads. By integrating multiple fatigue damage characterization methods and performing multi-condition, multi-scale fatigue tests, a fatigue life prediction model that incorporates micro-damage mechanisms will be developed, providing a key tool for the concurrent design of materials and structures to meet product performance criteria.